System Integration department

Industrial Automation | System Integration | Software Development

Integration the process of connecting different sub-systems (components) into a single larger system

Mheco Inc.

System Integration Capabilities

Our superior integration services are:

- System Architecture Development

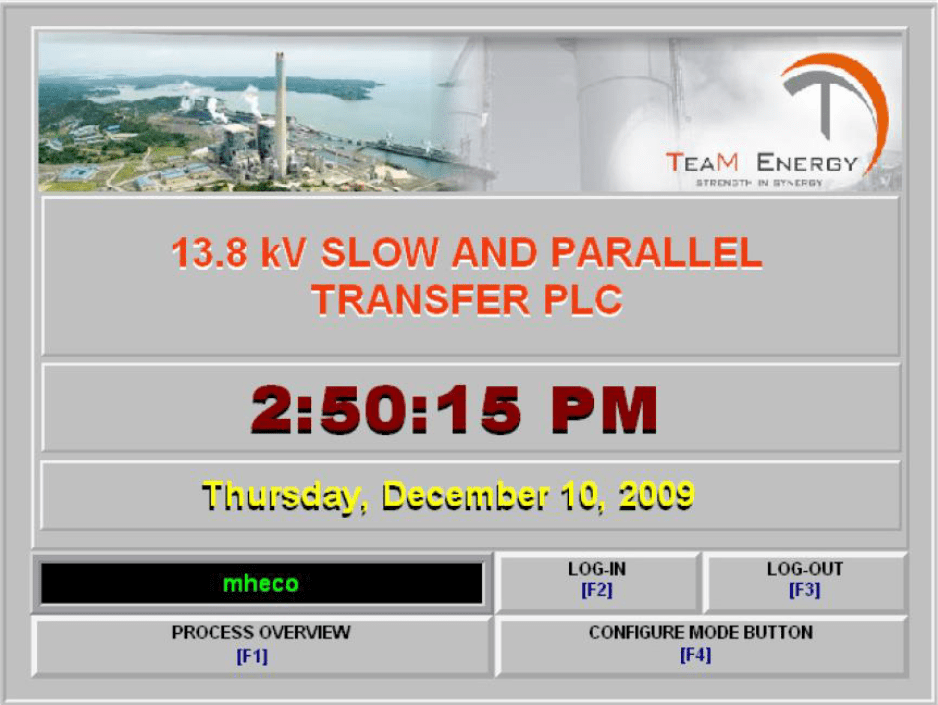

- DCS/PLC Programming

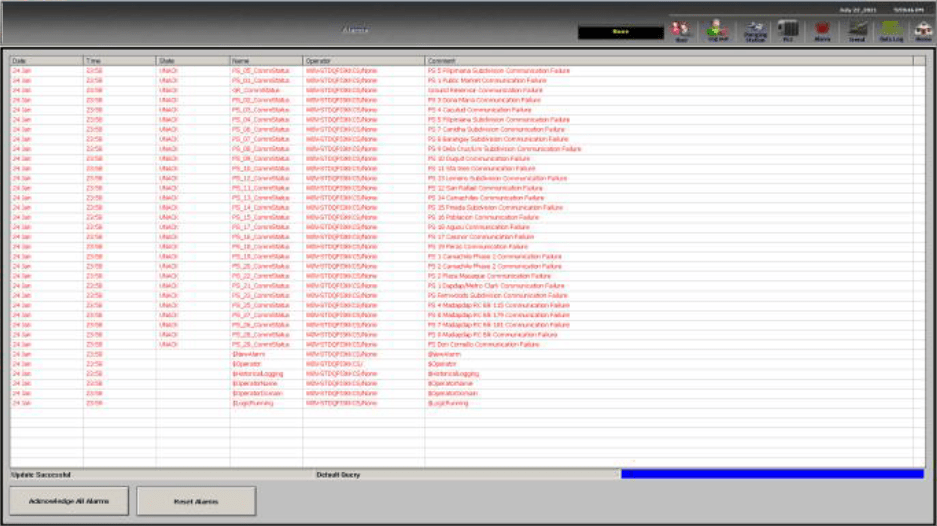

- SCADA/HMI Development

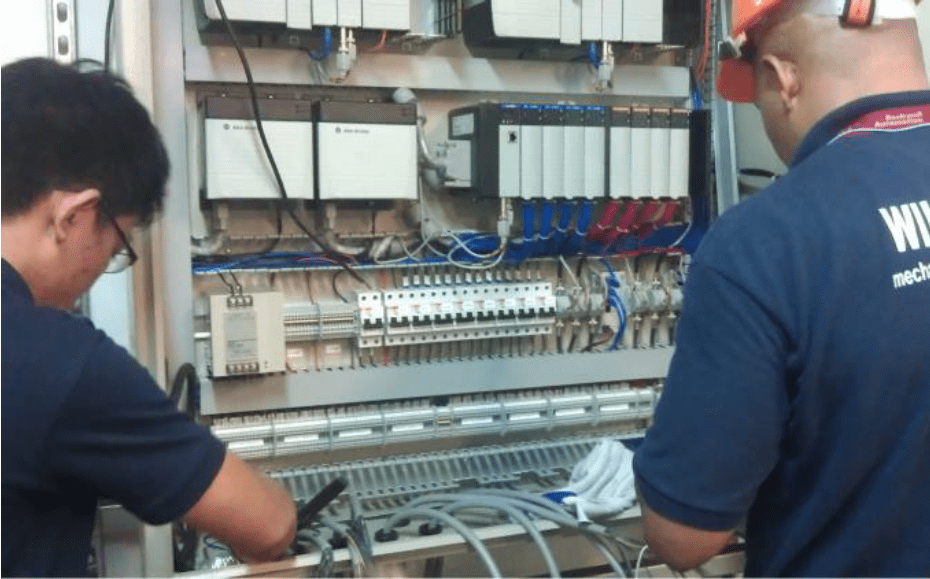

- Panel Building and Wiring Integration

- Instrumentation Works

- After Sales Support and Maintenance

Established in 1984, Mheco Inc. earned its respect in the industry as one of the best suppliers of Mechanical Handling products from Germany, United States and other countries. Because of our good track record in giving the best Technical Assistance to our customer and After Sales Service.

We offer a unique blend of talent to help you and your company install brand new, or upgrade existing, industrial control systems. Our services include System Architecture Development, DCS/PLC Programming, SCADA/HMI Development, Panel Building and Wiring Integration, Instrumentation Works, After Sales Support and Maintenance, and Training.

We design and build instrumentation and control systems for water, wastewater, brewery, cement, paper mining, forestry, manufacturing, and other industrial applications, as well as providing the associated testing, documentation, installation supervision, operator training, and maintenance services to support these systems.

As a Rockwell Automation Recognized System Integrator (RcSI), Wonderware Certified System Integrator Partner, ThinManager Certified Integrator and Siemens System Integrator, mheco inc. is able to provide components and subsystems from a wide variety of manufacturers in order to achieve the most cost-effective solution for our customers. We have the expertise and experience to provide a custom-fit solution for your needs.

Projects

(MES / Traceability Solution)

Networked software with SQL database that records plant floor information

It records data starting from Raw Materials Tipping to Finished Goods along with their respective manufacturing parameters like temperature, specific gravity, vitamin content, etc.

Generates formatted reports that serves as a decision making tool for production managers and supervisors

(Machine Monitoring System)

The Automated COMPAS is a program initially developed to automatically monitor stoppages on the machines.

It links different databases such as AS400, Compas database, and QM6 database.

It also generates a work order for stoppages requiring technical/ mechanical assistance.

(OEE / Line Efficiency)

The ADMS tracks the output produced within the line, the stoppages occurred and their corresponding effective contribution. With these data, along with the standards maintained, ADMS produces a semi-real time efficiency.

It can produce reports indicating what machines are major contributors to efficiency losses and per day efficiency.

Other functionalities are: tracking if the output is near target, crewing maintenance and assignment, and machine speed trending.

(Recipe Management and Scheduling)

Description:

The Weighing Control System automatically is an enhancement of ingredient processing with the use of barcode scanners.

It eliminates manual processing of weight data and ensures completeness of process ingredients.

(Recipe Management and Monitoring)

It eliminates manual processing of weight data and ensures completeness of ingredients for production.

Partners

Some of Our Valued Clients

Learn More About Us

Contact us now and let us help you increase your firms productivity by improving the quality of work through system integration.

System Integration Department

Suite 812 Herrera Tower V.A Rufino St. (formerly Herrera) cor. Valero Sts., Salcedo Vill., Makati City, Philippines

+63 (02) 8845 – 1419